Description

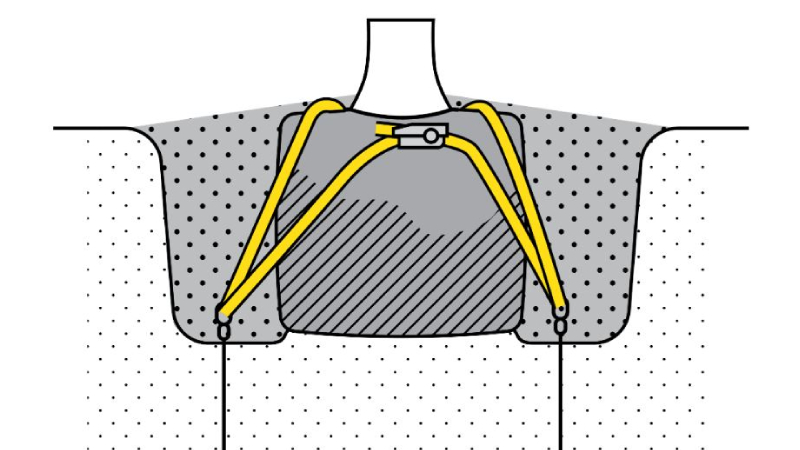

The DUCKBILL® Root ball Kit – Model 88 is the anchoring solution of choice when guy pole or stake systems are not possible or desirable in locations such as playgrounds, parks or where sidewalk plantings are required.

The DUCKBILL® Root Ball Kit is specifically designed to hold the tree’s root ball firmly in place, with only the tree protruding above the ground. Each Root Ball Kit comes with 3 DUCKBILL® anchors with D-ring and 1 strap with hand ratchet

Saving time and labor, patented Duckbill® Anchors work like toggle bolts in the soil. Duckbill Anchors are driven into the ground (with no holes, no digging and no concrete), providing a safe and environmentally sensitive installation.

An upward pull on the anchor tendon rotates the Duckbill Anchor into a perpendicular “load lock” position in undisturbed soil. Duckbill Anchor systems offer the most effective, lightweight, economical solutions to any anchoring application, large or small.

Advantages:

- Fast, easy, safe installation

- No poles or stakes

- Completely underground

*One kit anchors one tree. Drive steel additional.

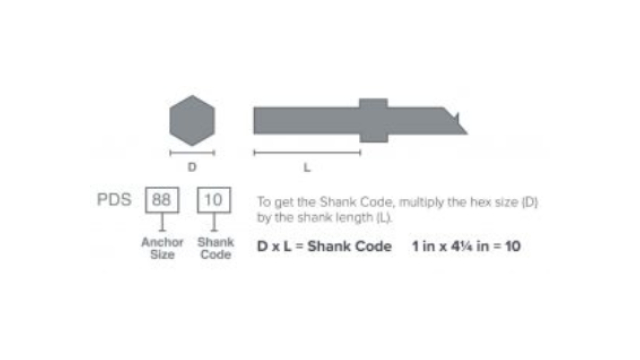

How to Select Power Drive Steel

Determine the Duckbill Anchor to be installedMeasure hex size (D) across flats of a shank that fits the hammerMeasure shank length (L) from top of hex to bottom of collarCall with special shank sizes or if you need more information on determining what drive steel is needed

Each Duckbill Anchor has unique drive steel determined by the jack hammer and the anchor model.

EXAMPLE: For a Model 88 Anchor with 1 in x 4 ¼ in shank, drive steel is PDS8810.

Specifications

Meet the Team

Raymond Chow has been involved with the geosynthetics industry for over 15 years. Graduating with a First Class Honours degree in Civil Engineering at the University of Sydney, Raymond specialiSes in retaining wall designs, soft ground improvement, channel and slope protection, and on-site storm water management.

Raymond has been on various technical committees addressing geosynthetics, including testing, specification and durability issues.

Join our next session by emailing us at technical@polyfabrics.com.au