Description

Butyl Tape is a versatile adhesive solution featuring high water resistance, ideal for various sealing, joining, and waterproofing applications. Its butyl rubber adhesive is coated on a polyethylene net, providing dimensional stability, while a siliconized kraft paper release liner ensures easy application. The adhesive is designed to conform to rough and textured surfaces, making it suitable for a wide range of uses. With its black color, Butyl Tape offers a discreet and professional finish.

Roll Size: 75mm x 15m

Utilization

- Fixing and sealing joints for waterproofing in construction and civil engineering projects.

- Joining and sealing membranes for enhanced waterproofing.

- Holding and sealing sisalation in the HVAC (Heating, Ventilation, and Air Conditioning) industry.

- Mounting lightweight signage to textured surfaces, such as rendered concrete.

- Joining and mounting Corex or Corflute materials.

- Vibration isolation of audio parts for improved sound quality and performance.

Installation best procedure while working with butyl tape:

1. At the joint / seam area, position the geomembranes with an overlap of ± 100-120 mm. The geomembranes must be laid flat and without any tension.

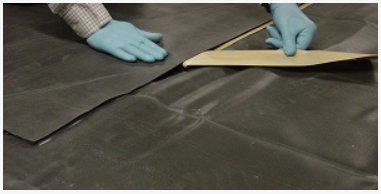

2. Fold back the geomembrane which is located in the top position. Remove any excess dust and dirt on the area where the Butyl tape is to be applied (top and bottom seams).

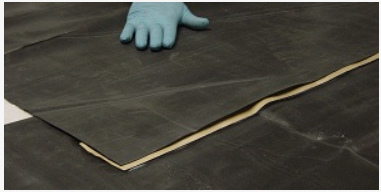

3. Position the Butyl tape on the bottom sheet and align the edge of tape with the geomembrane.

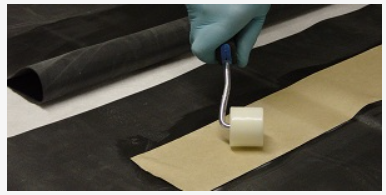

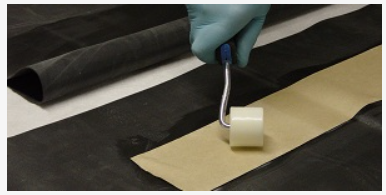

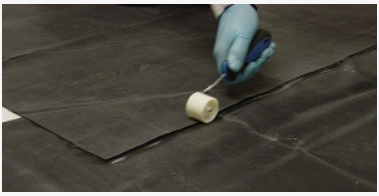

4. Remove the underside paper of the Butyl tape and stick down. If hand pressure is not sufficient to seal, since it does not provide uniform compression use a hand roller applying firm pressure across the tape surface area. It is essential to remove any air that may be trapped between the liner and tape.

5. Position the upper geomembrane sheet onto the Butyl tape.

6. Remove the top side paper of the Butyl tape and stick as you peel (this should be done at a steady pace and not rushed). If hand pressure is not sufficient to seal, since it does not provide uniform compression use a hand roller applying firm pressure across the tape surface area. It is essential to remove any air that may be trapped between the liner and tape.

7. Once the Butyl tape has been applied, roll the seam with the rubber hand roller, both across the seam and along its entire length to ensure that the geomembrane and tape are completely bound tightly.

All Options Available

| BUTYLTAPE7515 | Butyl Tape |

Applications

- Fixing & sealing joints

- Waterproofing construction

- Joining & sealing membranes

- HVAC sealing

- Mounting signage.

- Vibration isolation

Meet the Team

Raymond Chow has been involved with the geosynthetics industry for over 15 years. Graduating with a First Class Honours degree in Civil Engineering at the University of Sydney, Raymond specialiSes in retaining wall designs, soft ground improvement, channel and slope protection, and on-site storm water management.

Raymond has been on various technical committees addressing geosynthetics, including testing, specification and durability issues.

Join our next session by emailing us at technical@polyfabrics.com.au