Why Work with Polyfabrics?

Polyfabrics can provide design assistance throughout the 3 phases critical to the implementation of a successful onsite detention system.

1. Design, analysis and site inspection

Our technical team is here to support our clients with design assistance and Stormwater Detention or Retention Tank Design Capabilities. We can support you by inspecting the site and assessing conditions, reviewing regulatory requirements, analysing the functional relationships and area requirements and preparing preliminary drawings and schematic design reports.

2. In-house tank assembly service

Polyfabrics can supply assembled modules to expedite installation and deliver a solution that is cheaper and easier for the contractor. This also guarantees correct assembly and eliminates errors and reassembly time, as well as allowing labourers and engineers to focus on other project tasks instead of assembling tanks. This method is highly cost-effective, typically delivering a 33% reduction in assembly costs.

3. On site project and installation support

Our team can assist throughout the project including installation support and advice during the project, for example, if unexpected ground conditions are encountered. The below case study outlines our complete end-to-end solution for a recent residential development project in Warrnambool.

Case Study: Warrnambool Residential Estate, Stage 4

Project: Riverland Estate, Stage 4

Location: Warrnambool, VIC

Products:

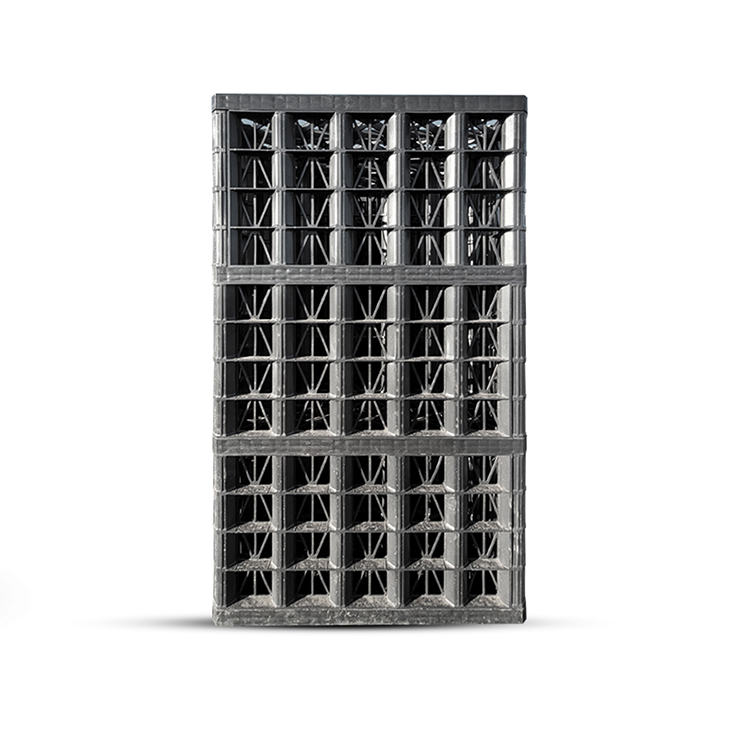

- MastaSTM Stormwater Module,

- MastaSTM Unidirectional Module

- mastaTEX Non-woven Class C Geotextile

- mastaGRID 3030 Composite Geogrid

- Geomasta HDPE Liner 1mm

- Geomasta HDPE Bio-Liner

- Geomasta HDPE Bio-Liner Boot Flange

The Project

Riverland Estate is a master-planned community in Warrnambool. Currently under development, the site sits on the banks of the Merri River and it is subject to Warrnambool City Council’s requirements to ensure stormwater runoff is adequately managed.

Underground storage cells would need to be installed beneath the paved surface of nearby Morris and Wollaston Roads, totalling 494m3 or 494,000L of underground stormwater storage.

These cells temporarily retain stormwater in the case of a 20% AEP, as well as managing any additional runoff generated by residential development before it is finally discharged into the Merri River.

Challenges

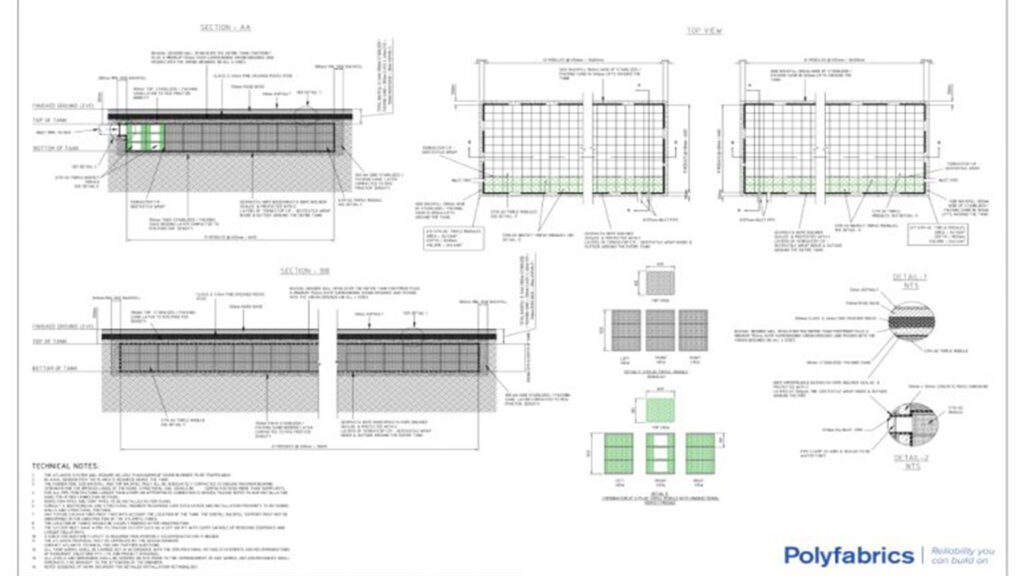

The underground stormwater tanks needed to be designed to withstand the desired pavement load for light-duty asphalt pavement as per Austroads specifications. To meet this spec, a configuration of MastaSTM Stormwater Triple modules with a compressive strength of 850 kPa / sqm was assessed as a suitable solution.

Additionally, tank invert levels were also dropped to increase cover over the tank. This would ensure good load dispersion across the soil, reducing pressures on the tank and helping to achieve the desired strength in the long term.

The main project requirement was for 494m3 or 494,000L of water storage with a 375mm inline inlet and 300mm outlet pipes for easy tank maintenance and inspection.

A combination of MastaSTM Triple Modules and Unidirectional Triple Modules, totalling 1342 triple modules were used, providing the necessary water storage.

An external pipe boot made from Geomasta HDPE Bio-Liner was used to connect the 375mm inlet pipe to the MastaSTM Unidirectional Modules with 300mm outlet pipes installed inline to the MastaSTM Unidirectional Modules for easy maintenance access.

This tank and pipe arrangement perfectly met the project requirements.

Adequate flush-out points were also a critical feature, so MastaSTM Unidirectional Modules were implemented along the low section of the tanks to provide linear access for high-flow flush-outs and maintenance of the tanks.

MastaSTM Unidirectional Modules also provided an added advantage for the Warrnambool City Council maintenance team to inspect the tanks with remote-controlled CCTV cameras.

Our Solution

The Polyfabrics team was able to assist the contractor with a full range of products to meet different requirements across this project.

- Detention tanks – A combination of MastaSTM Stormwater modules totalling 1342 triple modules was wrapped with Geomasta HDPE Bio-Liner and mastaTEX Non-woven Class C geotextile.

These geotextiles were used to provide the desired water storage, with an external pipe boot made from Geomasta HDPE Bio-Liner installed to connect the 375mm inlet pipe to the MastaSTM Unidirectional Modules

In addition, 300mm outlet pipes were installed inline to the MastaSTM Unidirectional Modules for easy maintenance access.

Geomasta HDPE Bio-Liner was used to line the tanks to ensure water retention. Pre-manufactured Geomasta HDPE Bio-Liner ensured no welding on site, thereby saving heavy costs in labour, time and 3rd party welder costs.

- Well-designed pipe connections – Pipe boot flanges made from Geomasta HDPE Bio-Liners were to be used to connect all inlet, outlet, inspection, and ventilation shafts to the mastaSTM Storage system to ensure reliable leak-proof joins.

- Liner protection – mastaTEX Non-Woven Class C geotextile was used to cushion the Geomasta HDPE Bio-Liner on the inside and outside of the tank lining system. The addition of a nonwoven geotextile helps to protect the liner from any damage during and after installation.

An additional layer of 1mm thick HDPE liner was also installed underneath the MastaSTM Unidirectional Modules to provide a rigid track for remotely operated CCTV maintenance systems. - Subgrade reinforcement – Finally, a layer of mastaGRID 3030 composite geogrid was installed over the soil cover of the tanks. Positioned under the pavement subbase, this geogrid product is ideal for assisting with load dispersion and subgrade reinforcement.

Step 1:

Excavate to the required footprint and depth and prepare base.

Step 2:

Install Mastatex non-woven class C on the base (cushion geotextile)

Step 3:

Install Geomasta HDPE Bio-Liner (impermeable liner for water retention)

Step 4:

Install MastaTex Non-woven Class C Protection geotextile (protection geotextile)

Step 5:

Place 1mm thick HDPE Liner, MastaSTM Triple Modules and MastaSTM Unidirectional Modules

Step 6:

Once all tanks are placed in position wrap the protection geotextile around the tank

Step 7:

Now wrap the Geomasta HDPE Bio-Liner and seal using 75mm wide Butyl Tape

Step 8:

Finally wrap the cushion geotextile around the tank.

Step 9:

Connect the inlet and the outlet pipes using Geomasta Bio-Liner Boot Flange

Step 10:

Backfill Sides with Stabilised Packing Sand in 300mm lifts and compact.

Step 11:

Place 180mm of compacted top stabilised sand and install MastaGrid 3030 GT geogrid on the top. Now pavement can be constructed on top as required.