Membranes and Other Solutions Available from Polyfabrics

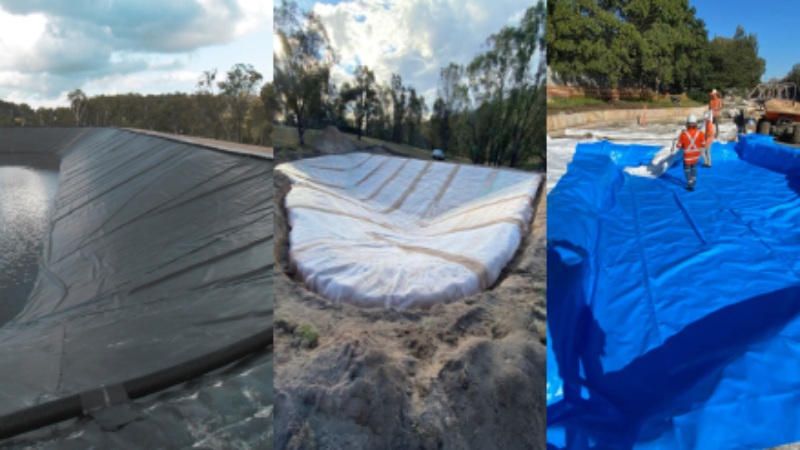

The use of membranes to line ponds and dams in civil and environmental applications is becoming more widespread as the industry develops a greater understanding of the effects of contaminated ground conditions on structures and the environment.

Polyfabrics offers a range of lining systems including Geomembranes and Geosynthetic Clay Liners (GCLs) with each offering different benefits for a diverse range of applications.

What is the Purpose of a Lining System?

Lining systems act as barriers within the geosynthetic families. The lining system will contain any liquid that is placed there, and hold it in place until it is either removed or evaporated.

Retention ponds can be used for storing everything from stormwater to mining tailings, and can be designed to be completely waterproof or with a permeable base to allow liquid to eventually percolate through. Any ponds that could potentially contain toxic chemicals or pollutants, such as landfill leachate, need to remain absolutely waterproof to ensure harmful substances don’t enter the surrounding environment.

With all pond lining applications, proper installation is critical and virtually all lining systems will only work effectively if they are professionally installed and welded together. Plastic lining systems can also be easily damaged, therefore a protection geotextile is often required to ensure the safety and sustainability of your lining system.

Types of Liners for Ponds and Dams

HDPE Liners – 1.5mm or 2mm thick

Polyfabrics’ HDPE Liners are most commonly used in the lining of channels, small dams and other containment structures.

Due to its excellent chemical resistance and low material cost, HDPE is extremely popular in lining applications requiring low permeability and high strength/density ratio. HDPE is also harder and more opaque and can withstand higher temperatures (120°C for short periods).

Prefabricated HDPE Bio Liners

GEOmasta® HDPE Bio-Liner is a premium woven polyethylene fabric with 2 layers of interlocked HDPE reinforcing mesh built into the liner.

The HDPE woven base with LDPE coatings offers excellent tensile and tear strength, and the liners are made to order up to 20m x 40m with a fast turnaround (typically 3 – 5 days).

Opting for a custom prefabricated liner means there is no welding required, making for a faster and easier installation on site.

Geosynthetic Clay Liners (GCLs)

Geosynthetic Clay Liners consist of a layer of sodium bentonite granules encapsulated by layers of durable geotextiles and shear reinforced by needle punching together all components.

The material is typically anchored in a trench around the perimeter of a containment basin to provide the required pullout resistance. Products such as Bentoliner GCLs are ideal for containment applications, providing a cost-effective engineered solution.

Concrete on a Roll

mastaTEX® Concrete is a needle-punched composite, made of concrete-sand mix embedded and fixed between two layers of geotextile.

This combines the strength of concrete with the flexibility of a geotextile layer. Without the need for slow, premixed concrete processes, mastaTEX® Concrete helps speed up projects and reduce costs, allowing relatively fast installation. Concrete on a roll is typically used for channels, trenches and embankments but may also be used as a replacement for shotcrete in the construction of smaller ponds and dams.

How to Determine the Best Liner for Your Project

The Polyfabrics team is here to help you select the right product for your project. Contact our engineering team for assistance in selecting the right lining system.