CCX™ is part of a revolutionary class of construction materials called Geosynthetic Cementitious Composite Mats and Barriers (GCCM/Bs). It is a flexible, concrete filled geosynthetic, that hardens on hydration to form a thin, durable, water proof concrete layer.

Essentially, it’s Concrete on a Roll™. CCX™ allows concrete installation without the need for plant or mixing equipment while also reducing vehicle movements and contractor burden. Simply unroll and just add water.

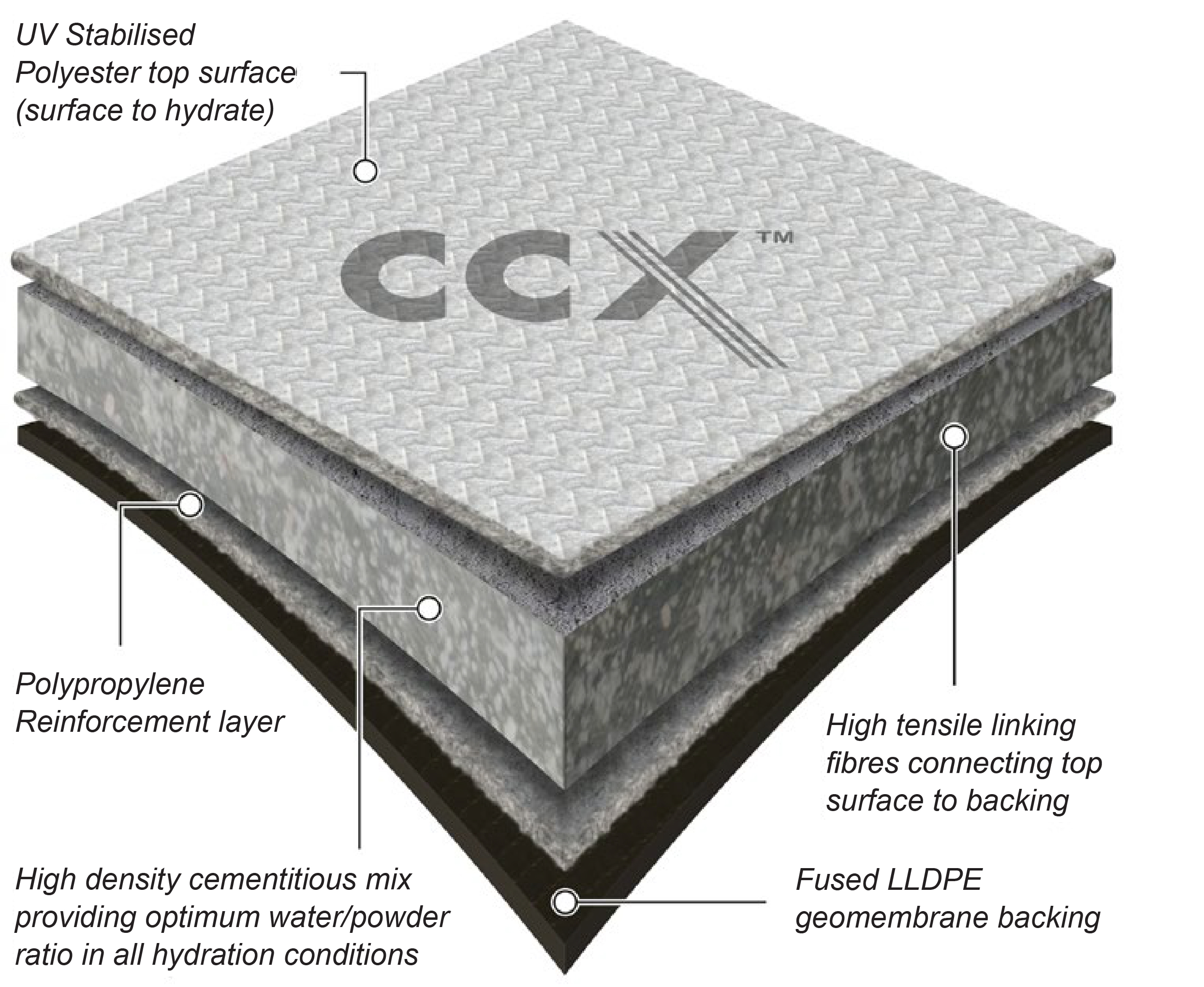

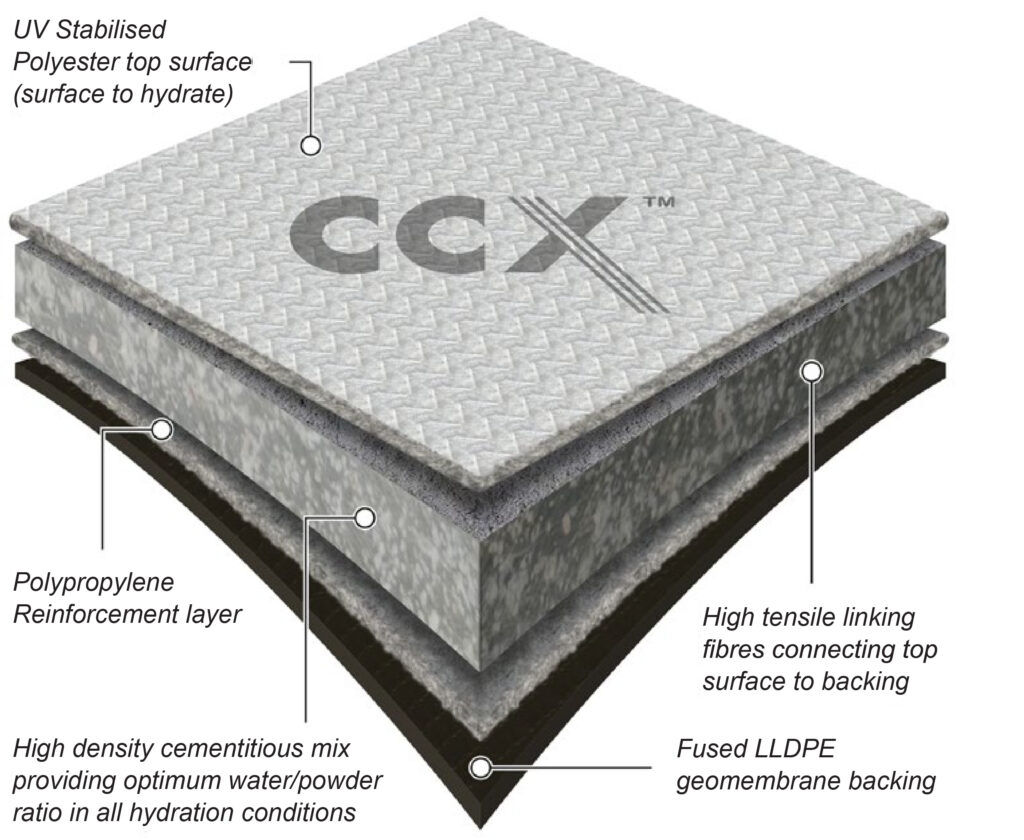

CCX™ consists of two interconnected layers of geotextile that encapsulate a specially formulated dry concrete mix. An LLDPE geomembrane backing ensures the material has very low permeability.

CCX™ can be hydrated either by spraying or by being fully immersed in water. CCX™ products exceed the minimum requirements of ASTM D8364 – Standard Specification for GCCM Materials.

Benefits of CCX™ as a Bulk Water Infrastructure Liner

Rapid Installation

The speed of installation and high early strength gain means that infrastructure down-time is minimised. In critical infrastructure, where maintenance shut-down periods are fixed, this allows for much greater areas to be lined or repaired.

Reduced Seepage

Over time conventional concrete liners can suffer from widespread cracking due to differential ground movement, leading to significant seepage losses, undermining and, in the worst instances, complete

channel collapse. CCX™ can accommodate a high level of differential ground movement due to the fibre reinforcement imbedded within the its structure. This prevents crack propagation whilst retaining low levels of permeability.

Composite Solution

Composite Solution CCX™ combines the low permeability of a geomembrane with the protection and durability of concrete. CCX™ can be installed as rapidly as conventional geosynthetics and 24 hours from hydration will cure to create a hard-wearing concrete liner which is ready to use.

Low Logistical Footprint

CCX™ has an un-hydrated unit weight of 14.5-15.5kg/m2 compared to ~220kg/m2 for 10cm of cured concrete. This means it is typically more than 10x more efficient in terms of the logistical footprint, requiring fewer trucks and reducing operational overheads.

A CCX™ Irrigation Canal Installation

A CCX™ Bulk Water Infrastructure Remediation Installation

Properties of CCX™

- High Impermeability: CCX™ has an LLDPE geomembrane backing ensuring the material has very low permeability, significantly reducing or eliminating seepage losses.

- Durable: CCX™ has a high degree of durability with abrasion resistance more than 3.5 times that of standard OPC concrete.

- Long-Term Performance: CCX™ has very good long-term performance with a life expectancy in excess of 50 years.

- Lower Carbon: CCX™ is a carbon efficient concrete solution that offers significant embodied carbon reduction compared to conventional concrete linings.

CCX™ GCCM/B Applications

Bulk Water Infrastructure Lining & Remediation

CCX™ can be rapidly unrolled to line earth canals as well as remediating existing concrete bulk water infrastructure. It is significantly faster, easier and more cost effective to install than conventional lining methods.

The LLDPE geomembrane backing to CCX™ ensures the material has very low permeability. The composite concrete top cover provides a high degree of long-term durability.

As a result, CCX™ is the ideal solution for the lining and remediation of channels and irrigation canals, increasing their operational life and reducing

water seepage losses.

1. Deploying Bulk Roll of CCX™

2. Pegging CCX™ within anchor trenches

3. Thermal welding of CCX-B™ LLDPE backing

4. Thermally bonding overlapping layers of CCX™

5. Hydration of CCX™

6. Backfilling anchor trenches to prevent ingress

Accessories

| Fixing Component | SKU | Description |

|---|---|---|

| Screws | CCCNPSS-4.0/35 | CC Collated Screw 4.0mx35mm SS 1000pk |

| Pin 12mm / 50mm Head | CCP250/12 | CC PIN 250 x 12mm HDG |

| Pin 16mm / 50mm Head | CCP380/16 | CC Pin 380 x 16mm HDG |

| Pin 13mm / 20mm Head | TPIN360 | M/TEX Concrete 360mm Fixing Pin 13mm |

| Sealant Cartridge | 40-121970 | T-Rex Power Fast Grab 290ml Steel Grey |

| Sealant Sausage | 40-147559 | T-rex Power Fast Grab 600ml Steel Grey |

Applications

- Bulk Water Infrastructure Lining & Remediation

Meet the Team

Raymond Chow has been involved with the geosynthetics industry for over 15 years. Graduating with a First Class Honours degree in Civil Engineering at the University of Sydney, Raymond specialises in retaining wall designs, soft ground improvement, channel and slope protection, and on-site storm water management.

Raymond has been on various technical committees addressing geosynthetics, including testing, specification and durability issues.

Join our next session by emailing us at technical@polyfabrics.com.au