Description

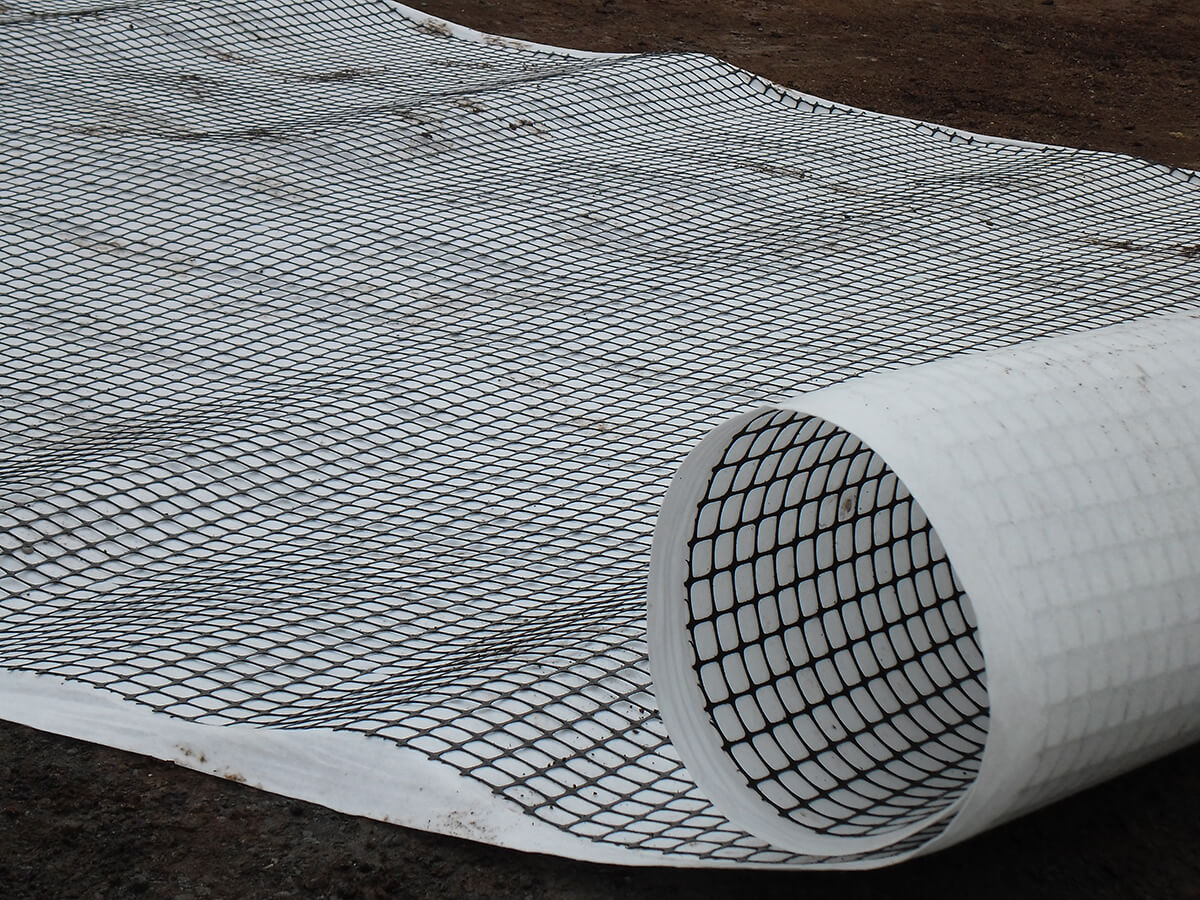

mastaGRID® GT Geogrid 20/20 – 3.9m x 50m

Pavement/ Asphalt Reinforcement

mastaGRID® GT is a geocomposite made up of a biaxial geogrid laminated to a nonwoven geotextile. Polymer: Polypropylene Geogrid(PP) and Geotextile Polyester (PET) or Polypropylene (PP).

Benefits of mastaGRID® GT & Geotextile Geocomposites

- Distribution of loads and therefore reducing stress concentration over the soil.

- The geogrid’s structural junctions, rigid ribs and thick walls help lock aggregate, increasing its shear resistance. As a result when a vertical load is applied, the aggregate is restrained by the ribs reducing deformation (lateral restraint).

- Decrease in long term deformation (creep).

- Increase in load distribution (bearing capacity increase).

Resistance to ultra violet light

The product displays excellent resistance to UV light due to its high carbon content. Weathering-grade carbon black is dispersed into the polymer matrix of the mastaGRID® GT Biaxial Geogrid, which extends its life in exposed conditions.

Chemical & biological resistance

mastaGRID® GT Biaxial Geogrids are manufactured from polypropylene which is unaffected by chemicals such as acids, alkalis and salts, normally found in soils. As it is not a nutrient, it is unaffected by micro-organisms found in soil.

Placement

Certain building sites require access to heavy construction vehicles such as cranes and drill rigs. Their tracks can exert ground pressures in excess of 400kPa. The use of rigid geogrids such as E Grid 3030 performs the same function as in the case of road pavement with the exception the load is more concentrated. The granular fill is substituted with rock to suit the aperture of the grid (40mm to 60mm) without fines initially. This forces the geogrid to lay flat. The more angular the rock is the better the locking, the greater shear strength and bearing capacity.

The geogrid layer is placed at the interface of the low CBR sub-base and the proposed platform. If the interface is below the water table, a filtration geotextile is placed first followed by the geogrid layer. The rock layer 200mm – 500mm is then placed uncompacted. The surface can then be blinded with finer material and compacted or in the case this layer becomes the drainage blanket, a geotextile is used followed by a finer soil.

Rigid geogrids behave differently to geotextiles even with similar or greater tensile strengths. Geotextiles transmit stresses to the soil through friction. They do not interlock with the aggregate the same way as a rigid geogrid with the apertures. For geotextiles to provide reinforcement they must go into tension (Tension Membrane Effect) and for this to occur requires large deformation and fixed wheel paths. This is difficult to control and design; as a result, the only function it achieves is separation.

The transmission of stress between soil and geogrid is obtainable only if the geogrid is rigid and integral. A woven geogrid constructed of high tensile polymer strands can hardly develop this function, as the structure is not integral and the transversal ribs can move along the longitudinal ribs without developing any interlocking effect.

Applications

mastaGRID® GT biaxial geogrid composites are used in applications where separation, filtration and reinforcement are required. When used in the optimal manner , mastaGRID® GT geogrid composites can reduce pavement depth and maximise the cost-benefit ratio.

Consult Polyfabrics Australasia or a certified Engineer for site specific installation instructions. Polyfabrics Australasia reserves the right to change its product specification at any time. It is the responsibility of the specifier and purchaser to ensure that product specifications used for design and procurement purposes are current and consistent with the products used in each instance.

mastaGRID® GT Specifications

Applications

- Reinforcement

- Filtration

- Pavement Stabilisation

- Subgrade Separation

- Slope Stabilisation

Resources

Meet the Team

Raymond Chow has been involved with the geosynthetics industry for over 15 years. Graduating with a First Class Honours degree in Civil Engineering at the University of Sydney, Raymond specialiSes in retaining wall designs, soft ground improvement, channel and slope protection, and on-site storm water management.

Raymond has been on various technical committees addressing geosynthetics, including testing, specification and durability issues.

Join our next session by emailing us at technical@polyfabrics.com.au

Case Studies

Polyfabrics supports Georgiou Group’s Panorama Drive Upgrade Project

The Panorama Drive upgrade project faced challenges with drainage system upgrades on a busy road.…

Polyfabrics Partners with Fulton Hogan on Walkerston Bypass Project

Our innovative TerraDrain® and FreDrain® Ultra solutions addressed water drainage, soil stabilisation, and waterproofing challenges…

Echuca Stormwater Detention and Batter Stabilisation

Polyfabrics' integration in Regional Victoria's stormwater project showcased innovative management and batter stabilisation, offering sustainable…