Polyfabrics’ HDPE Bioliner was crucial in efficiently lining ponds for the Snowy Hydro 2.0 project, overcoming environmental and logistical challenges with rapid production, easy installation, and proven performance.

Case Studies

Polyfabrics: 30-year success built on service excellence and global partnerships. Leading geosynthetic supplier, meeting civil engineering needs with top brands and tailored solutions. Explore our journey today.

On The Fast Track: Polyfabrics’ Solution for Sydney Motorsport Park

Polyfabrics provided an innovative solution for Sydney Motorsport Park’s upgrade, offering Flexiseal HD Reinforced bituminous tape. This self-adhesive membrane ensures durability and withstands conditions, crucial for motorcycle racing safety.

Transforming Urban Spaces: Creating a Suburban Oasis with Geomasta Sand Container

See how Rare-Enviro Pty Ltd transformed a disused water reservoir into a safe, sandy beach swimming zone using Polyfabrics innovative Geomasta Sand Containers. Learn about the challenges faced, solutions provided, and the successful outcome of this suburban oasis project.

Chambers Flat Road Widening: Overcoming Soft Subgrade with mastaTEX®

The Chambers Flat Road widening project faced road base compaction challenges due to soft subgrade. Polyfabrics’ innovative range of products provided an effective separation layer, enabling optimal compaction and a strong, durable road surface.

Polyfabrics supports Georgiou Group’s Panorama Drive Upgrade Project

The Panorama Drive upgrade project faced challenges with drainage system upgrades on a busy road. Polyfabrics provided innovative solutions and logistical support to ensure timely delivery of compliant materials, contributing to the project’s successful completion.

Echuca Stormwater Detention and Batter Stabilisation

Polyfabrics’ integration in Regional Victoria’s stormwater project showcased innovative management and batter stabilisation, offering sustainable solutions and setting a new benchmark in environmental project handling, ensuring both ecological integrity and infrastructural durability in urban development.

Wandana Gully Drainage Reserve Upgrade

Read how Polyfabrics helped transform Wandana Gully, with innovative erosion control and landscape design, using HDPE Eroweb and Tecmat products for stabilisation, ensuring a vibrant, safe community space and protecting local biodiversity.

Horse Ranch – Slope stability and erosion control with SeedMat TRM

Read how we successfully tackled slope stability and erosion control challenges at a horse ranch by utilising our SeedMat TRM. Instead of an expensive MSE retaining wall, we proposed lengthening the slope and installing the durable synthetic mat. This innovative solution resulted in significant cost savings, with expenses under $5,000 compared to the original estimate of over $50,000.

Tailored Bio Basin Solutions For Efficient Urban Development

Explore how Polyfabrics and Golding utilised the GEOmasta® Composite HDPE Bio-Liner for stormwater management in the Village, Stage 1 residential subdivision in Jimboomba. Discover how made-to-measure, cost-effective solutions can address unique challenges and promote environmental health in urban development projects.

Maximising subgrade stability with mastaGRID® geogrid solution

CPB Acciona JV overcame GeoGrid supply challenges by choosing Polyfabrics. Read how our unmatched supply chain, including extensive inventory and competitive pricing, made us the preferred partner.

Strengthening infrastructure resilience with Geotextile laminated TerraGrid®

Learn how our geotextile laminated Terragrid® played a crucial role in restoring Greens Road after the 2021 floods. With immediate reinforcement and stability, our high-strength solution overcame soft spots in the subgrade, allowing uninterrupted progress.

Getting it done for the Western Sydney Airport Project

We thrive on challenges, so when CPB Acciona JV approached us for geotextile materials for the Western Sydney Airport project, we eagerly offered our support. The project’s requirement for meeting customised specifications within a short lead-time highlighted the critical need for a reliable and efficient solution. In response, we promptly supplied high strength orange marker layer geotextile, which was manufactured in longer rolls to facilitate quicker installation and reduce costs.

Efficient and fail-proof solution for Adaminaby Sewerage Treatment Plant using MastaTEX Concrete

The Project RD Miller Specialised Earthworks is a leading construction company that specialises in earthworks, site preparation and civil construction projects. The company was contracted to construct the Adaminaby Sewerage Treatment Plant in New South Wales and in turn reached out to Polyfabrics to supply the product needed for this project. The Challenge The design […]

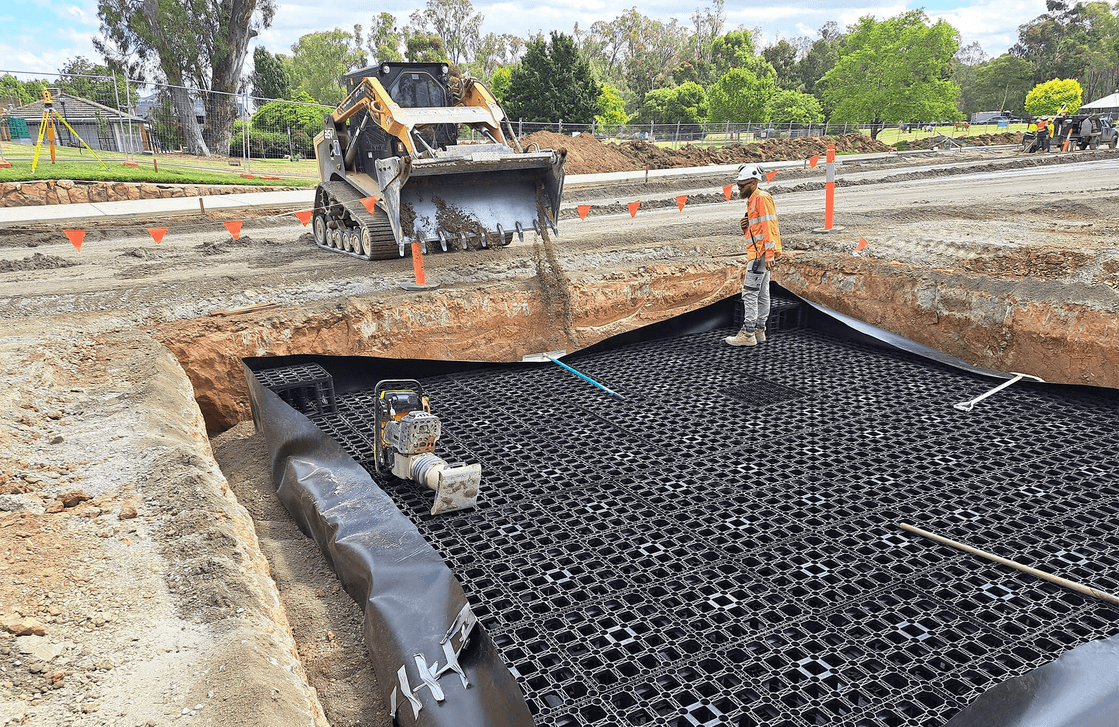

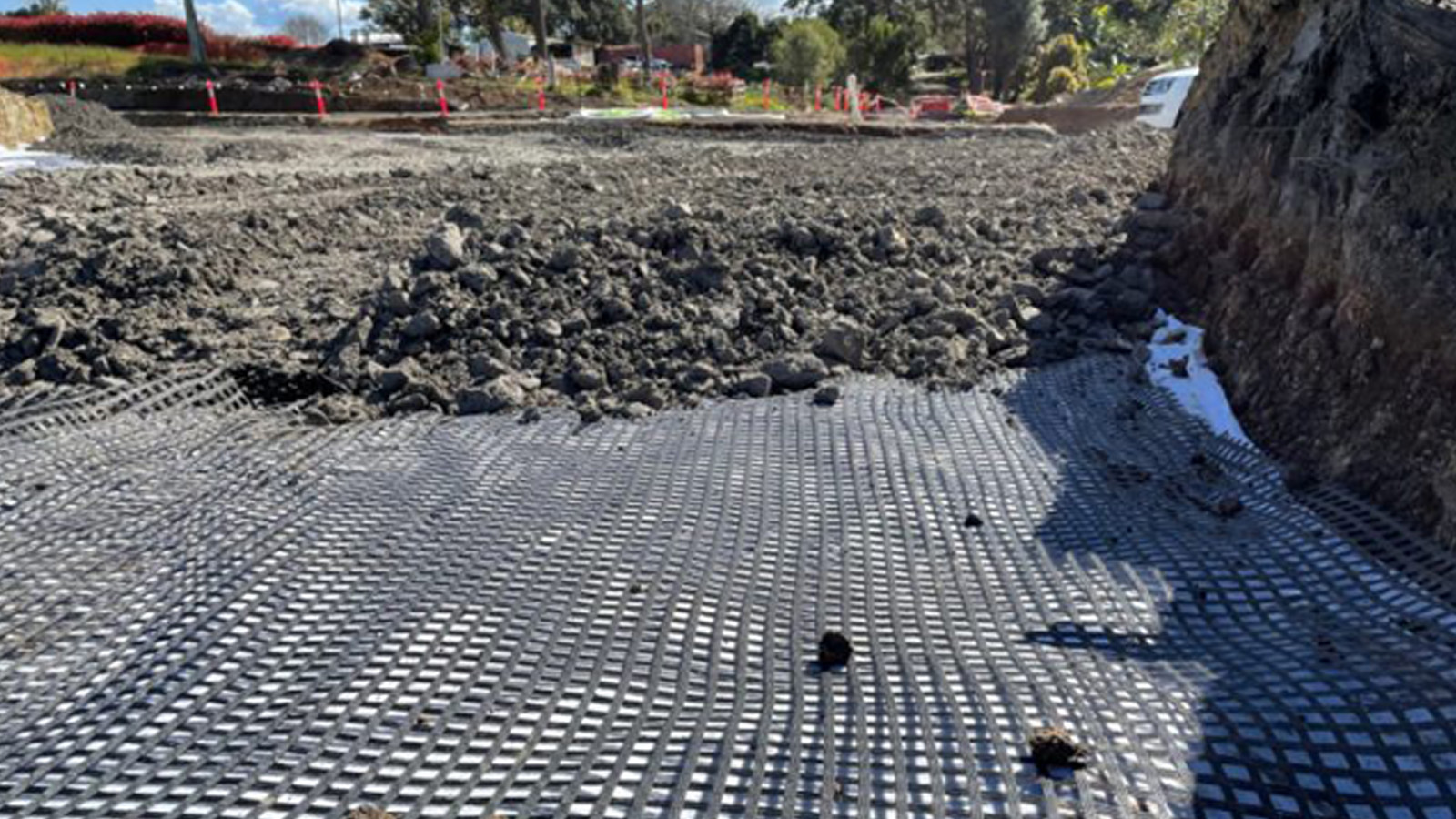

Stormwater management ponds at Deakin University

We were approached by our client to provide a solution for building a maintenance track to service the newly constructed stormwater management ponds at Deakin University. See how our EROWeb® geocell was the perfect choice.

Erosion prevention with Terramat PP5-10 Erosion Control Matting

Terramat PP5-10: The solution to prevent erosion and encourage vegetation growth in wetland projects. With 321% effectiveness and long-term sustainability, it’s the ideal choice.

Mastavault Megatree – Welsford Street Redevelopment

Greater Shepparton City Council is undertaking design and upgrade works to Welsford Street and the new design also included a full depth reconstructed road pavement designed to cater for the increased vehicle traffic volumes. See how our MastaVAULT Megatree was used in this project.

Preventing erosion with Geomasta Softrock Sand Containers

In Tweed River Shire, the Cudgeon Creek bank was being eroded which prompted the Tweed Shire Council to look for a solution. See how our Geomasta Softrock sand containers were used with this project to help with erosion control.

Lining existing drains for Mansfield Reservoir 3 Remediation Works

Polyfabrics Australia was involved in the Mansfield Reservoir 3 Remediation Works at Goulburn Valley Water. The project aimed to clean, reshape, and line existing drains that ranged from 1.5m – 6m wide x 350m long. The goal was to find a cost-effective and faster method of concreting the existing drains that would also reduce waste and installation time.

Moorebank Intermodal Project – Improving water quality with PFA’s expert solutions

Moorebank Intermodal is a major project that aims to enhance the rail transportation infrastructure in NSW and improve the efficiency and reliability of the rail network. However, Martinus Rail faced a significant challenge in preventing dirty water from getting into the drainage and ultimately into the Georges River.

Concrete on a roll for cost-effective industrial yard solutions

Narellan Pools needed to stabilize eroding rock slopes at their manufacturing facility in Picton, NSW, that were causing a hazard to valuable pool stock. Polyfabrics offered a solution with mastaTEX Concrete on a Roll, a cost-effective and low maintenance product made of concrete-sand mix embedded in geotextile.

Biodegradable coir products for Hornsby Quarry rehabilitation

The disused Hornsby Quarry North of Sydney is currently undergoing redevelopment to create an exciting new recreational area. To build this parkland, the Council had to manage the unique challenges of building on top of a sizable quarry void. Working with the team at Polyfabrics, the contractor used approximately 5000 square metres of TECmat Coir Mesh 700gsm, along with 200 metres of our ø200mm Ecolog Coir Logs.

Central Coast Council fixes drainage with Mastatex Concrete on a roll

Central Coast Council required a quick and affordable option for the planned swale drains alongside Old Maitland Rd, with traditional paving methods deemed unsuitable for the area. The Polyfabrics team assisted Central Coast Council with our mastaTEX Concrete on a Roll product. This easy-to-handle geotextile is impregnated with a concrete-sand mix that is simply rolled into place and then hydrated with water.

Fast Geosynthetic supply for Blacktown International Sportspark

The $100M Blacktown International Centre of Training Excellence is an ambitious project to deliver a world class multi-sports facility in the heart of Western Sydney. See how our mastaTEX® Hi Vis Layer was used for this project.

Terrastop® PP80 Woven Geotextile used for driveway subgrade improvement

The homeowners of a private residential area in Newcastle were looking to build a new carpark and driveway over soft ground. The Polyfabrics team was able to assist the contractor with a geosynthetic product that could deliver reinforcement properties to bridge the soft subgrade spots, and also act as a separation layer – all without breaking the bank.

Roadside slope reinforcement to protect from landslip risk

As part of the Victorian Government’s $115 million Inland Routes Program, several landslip sites will be reconstructed, stabilised, and retaining walls built, improving the strength of roads throughout Moyne Shire Council. See how our geogrids and jute mat was used to reinforce and stabilise these areas.

Quarry face earth buttress stabilisation for River Valley Stage 7D development

River Valley is a master-planned community located on the Maribyrnong river, with the Stage 7D tranche consisting of 10 lots earmarked for residential homes. The site sits alongside the retired quarry face, which required earth buttress stabilisation. Read why our TerraGrid® was chosen for this project.

Geogrid used in Greenfield Bridge Inn Road Upgrade

The Bridge Inn Road Upgrade project in Mernda aims to reduce congestion and improve traffic flow for motorists in Melbourne’s northeast. See how our team helped overcome the issue of the weak subgrade and low soil shear strength while still being able to construct the pavement on time and as per the design.

Spitfire Banks Drive, Pelican Waters – Landscape and Erosion

Spitfire Banks Drive is the main drive that will connect Central Park from the waterfront side of Pelican waters and is currently being constructed by Hall Contracting. Hall Contracting, in conjunction with Tectonic and Polyfabrics, selected the TerraStop® HS Woven 200/50 as the most suitable product to assist building a stable platform from which the piling rigs could operate.

Geosynthetics used in the Townsville Ring Road (Stage 5) project

The Townsville Ring Road Stage 5 project will deliver improved road safety, efficiency and travel time reliability for freight and passenger vehicles on the Bruce Highway in Townsville. See how our geosynthetics was used in this project.

Erosion Control for Penrith Flood Plains

Polyfabrics’ TerraMat® RF80, a high-strength steel mesh with anchoring ability, was used to stabilise the embankment for the $35M Log Cabin Hotel redevelopment in Penrith.

Geosynthetic solution for Bishop Drive, Mollymook

Bishop Drive links the Princes Highway with the popular holiday destinations of Narrawallee and Mollymook on NSW’s South Coast.

How Polyfabrics helped deliver cost savings for VicRoads highway project

The Victorian Government recently completed a project to improve safety on the Midland Highway, reducing road trauma and saving lives.

HDPE Bio-liner® Johnstons Creek Naturalisation

Polyfabrics’ Bio-liner® HDPE Composite Liner was used as a cost-effective solution to create a wetland for the renewal of Johnstons Creek in Sydney.

Eroweb Cellular Confinement for Landslide Remediation

The purpose of using geogrids stability on slopes channels when filled with locally sourced material.

Construction of Whitefriars College Multi Sports Courts

Revolutionizing Whitefriars College sports pavilion with mastaGRID® GT 30/30: conquer subgrade challenges, save time, cost, and the environment.

Flexible gabions fix flood-affected Brisbane boardwalk

Case study on how FastRock net gabion bags were used to fix flood-affected Brisbane boardwalk.